Non-standard devices

Line for the production of ventilation ducts

At the special request of our customer, we have designed and built a line for the production of large-section ventilation ducts for nuclear power plants. The line includes a sheet feeding module with a maximum format of 2000 x 6000 mm and a thickness of up to 10 mm, a rolling machine prepared for bending a special channel shape according to the customer’s design, a system for receiving channels from the rolling mill and delivering to a transport robot, and a special column system with a linear welding machine.

Autonomous production of pallet feet

The starting point for the creation of this line was the creation of several special machines and then the development of an extremely efficient and economical technology for the production of pallet legs. The number of machines was gradually increased and the devices were modernized all the time, increasing their efficiency. Fusing machines, dust-free saws, molding machines, depalletizers and palletizers cooperate in the technological line connected by the labyrinth of conveyors. At the last stage, the legs are transported to the pallet gluers, where the final product is created – an ecological paper pallet. In 2018, an ultra-efficient pallet gluer was added to the line, which is equipped with a robotic system for feeding the legs and a system for receiving the finished product.

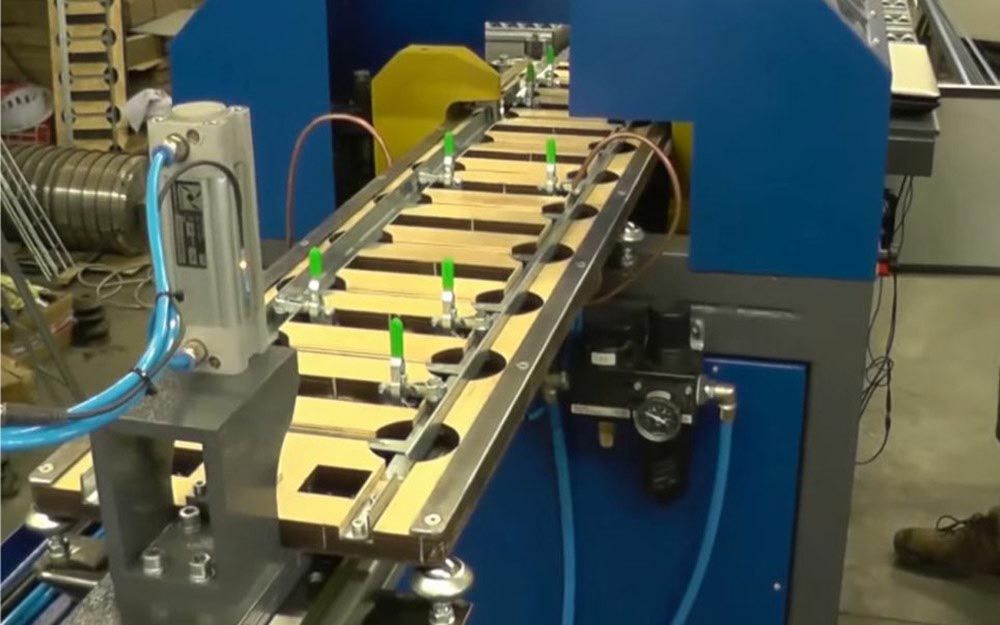

Automated snow fences production

We have designed, constructed and manufactured complete line for the production of snow fences in the TOX technology. Everything was based on the assumptions of our customer regarding productivity, quality, ease of use, raw material, etc. The line consists of a profiling machine and a device connecting the rungs with angles, using the TOX technology. The input material is a flat bar in a coil, and the final product is a ready-made snow fence. The concept of operation, construction, methods of moving, cutting, bending the material, the motors used, gears, transports, drivers and software have been developed by us.

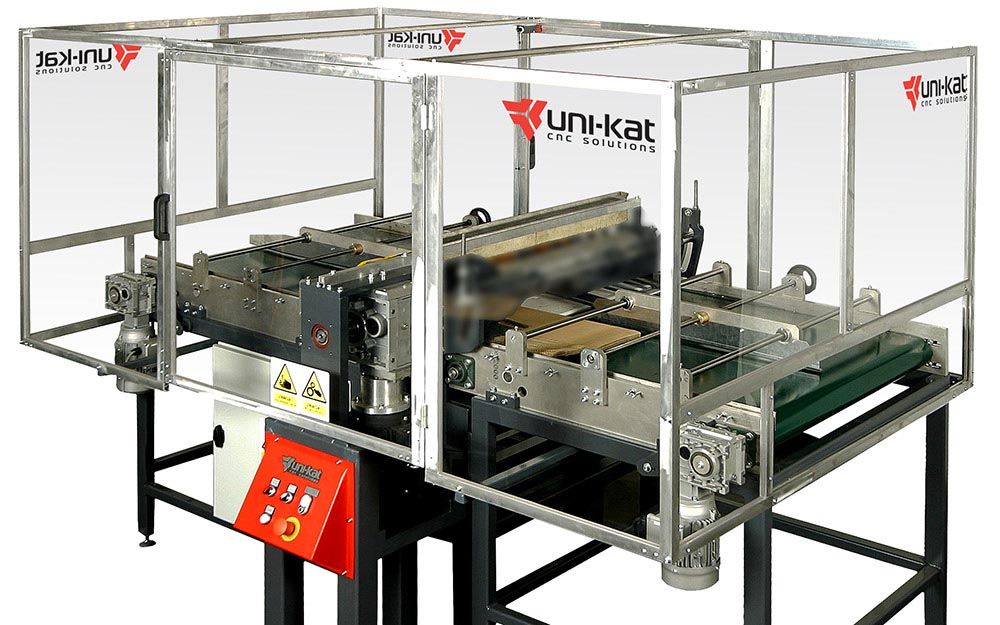

Cardboard cutting machine

The machine has been designed, constructed and manufactured based on the assumptions of our customer regarding productivity, quality, service, raw material, etc. The concept of operation, construction, methods of material handling and cutting, the motors used, gears, transports, controllers, software were developed by us. During construction works, we tested the applied solutions together with the customer’s technologists.

Thanks to our solution, the quality of the cut product has improved, with a simultaneous three-fold increase in production capacity. After 4 weeks of machine operation, the customer ordered another one.

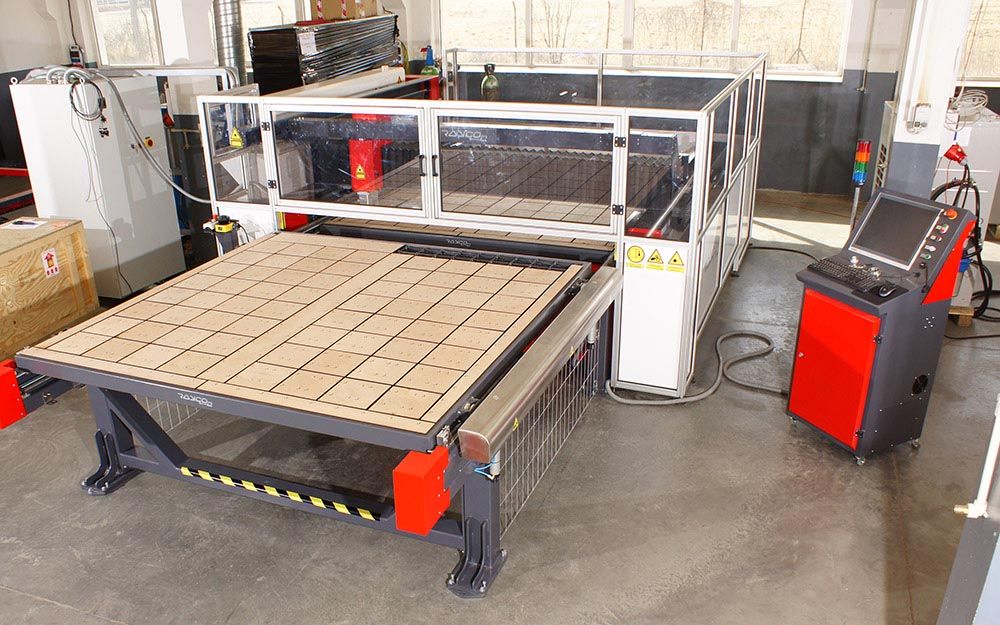

Carpet laser cutting machine

The cutter has been designed especially for a German company that equips skyscrapers with carpets. commissioned by a large manufacturer of CO2 laser sources

Together with the client, a complete system has been developed with the assumption of maximizing efficiency and maintaining the highest quality of the product, including a system of special ultra-fast exchangeable tables, special movable supports that allow the material to be safely placed on the table, a special hearth that supports the carpet on the largest possible surface, and much more.

Machine for the production of single-use cardboard pallets in Ikea standard

Constructed and built to order from the factory of the German concern, a large supplier of Ikea. It has the ability to glue the legs in virtually any configuration. Includes a built-in editable library of available palette types. The machine glues 4,000 to 8,000 pallet feet in a shift (8h), depending on the pallet configuration. After testing the first copy, the client ordered another 7 plotters.

PL

PL

DE

DE  RU

RU