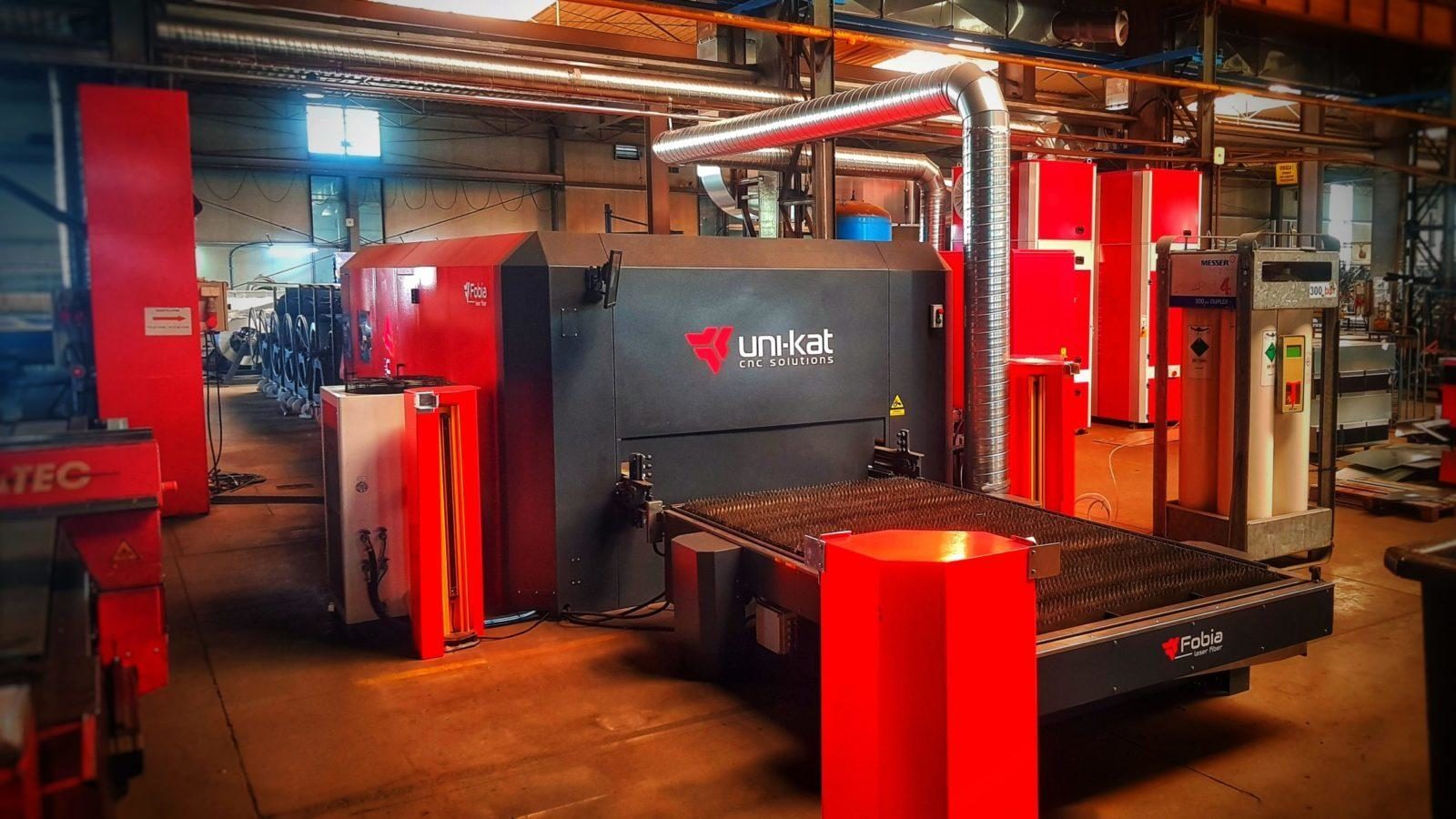

Complete production lines

Uni-kat’s complete production lines are an uncompromising solution for production facilities where productivity and low operating costs play a key role. Glimmer and Fobia cutters can be integrated with metal sheet decoiler with straightener and the system of interchangeable tables. This makes it possible to create an efficient, automatic line for thermal cutting, with enormous dynamics and speed of movements, while maintaining high accuracy. It is ideal for mass production, especially when quality is also important. Ideal for HVAC industry.

Customized machine

Each production line is individually adapted to the needs of our customers. Depending on the nature of the production, we will select and properly configure a plasma (Glimmer) or laser (Fobia) cutting machine.

Cooperation with Simmech Engineering resulted in the development of a special system that integrates our cutters with devices for decoiling and straightening sheets. We are the only manufacturer in Poland offering such solutions.

Decoiling, straightening and feeding system for metal sheets

The use of metal in coils directly gives a low cost of material purchase, but also is a significant reduction in the amount of waste. In addition, we eliminate the need to constantly load new sheets for cutting, which significantly increases the efficiency of the process. Familiarize yourself with the product offer from Simmech Engineering

Industrial Filtration Units

We offer modern filtering systems adapted to the size of the work tables of the selected device. The efficiency of air purification from solid fractions oscillates around 99.8%, thanks to which clean air can be directed back to the production hall.

Compressor combos with dryer and tank

Thanks to the modern screw and piston compressors we can achieve a much lower cost of thermal cutting, both plasma and laser. Cutting metals up to a thickness of 3 mm with air is as fast as cutting with nitrogen, and the difference in quality is practically imperceptible.

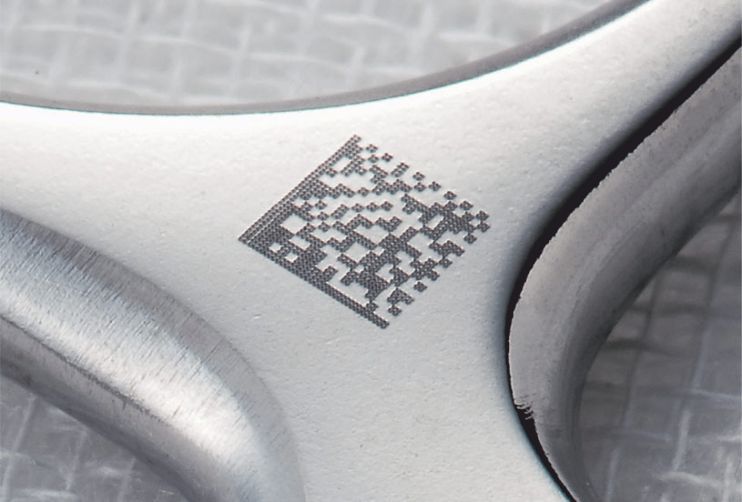

Ink marking system

Unlike traditional solutions, such as scribing and engraving, inkjet marking does not affect the structure of the material, and the print can be easily removed.

The print head works very well in companies with diversified production. Thus, we eliminate the need for manual description of details, which significantly reduces the preparatory processes for further production stages.

Contact us

Do you have questions or you are interested in the product and would like to receive an offer? Call us on +48 730 850 710, +48 570 740 950 or fill out the form below.

PL

PL

DE

DE  RU

RU