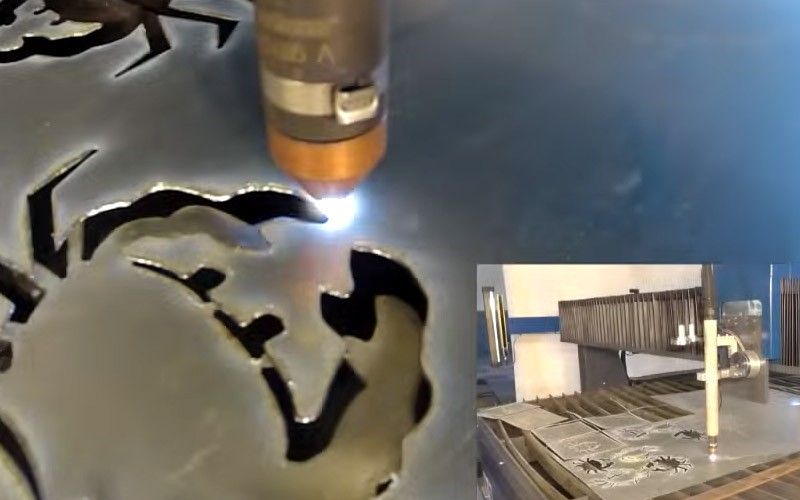

Glimmer was designed for extremly efficient thermal cutting of steel and other metals with a plasma or oxygen torch (oxygen-propane or oxygen-acetylene). The series of these machines is characterized by very high speed and dynamics of movements while maintaining high accuracy. Thanks to its versatility, rigid structure and very precise drive, it is perfect for any production. The operation of machine is simple and intuitive.

Solutions that you receive as standard:

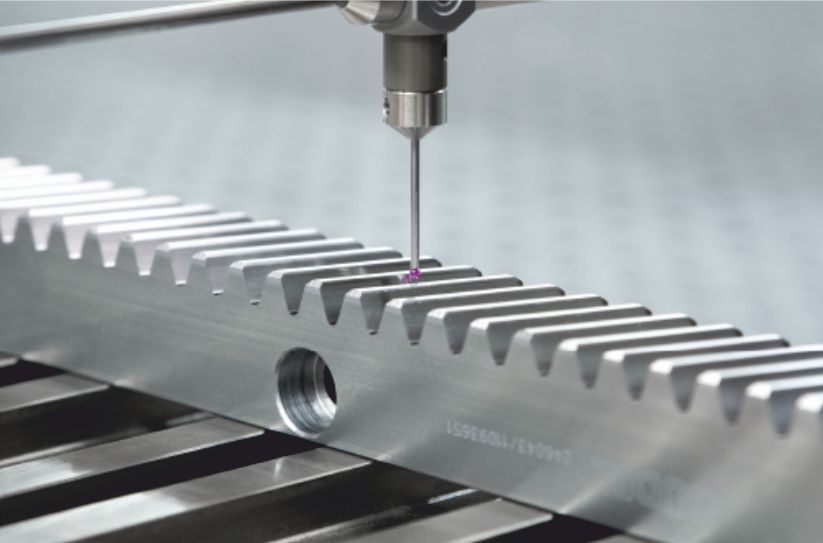

Precision helical drive

The drive transmission system in the Glimmer series machines is based on the highest quality helical racks. The physical properties of the inclined (helical) teeth result in excellent high-speed transmission while maintaining great precision of movements. Thanks to this, it is possible to achieve travel speeds of up to 85 m / min, without fear of losing dimensions, even on 12-meter sections.

Mobile control panel

All our poartal plasma-oxy cutters are equipped with a movable control cabinet, the range of which can be up to 5m. Thanks to this solution, it is much easier and more convenient for the operator to control the operation of the machine.

All the controlling electronics are inside the desktop. Thanks to the quick coupler system, the desktop can be disconnected from the machine in a very fast and easy way.

Hearth drawers

Most of our devices are equipped with waste drawers, which allow easy cleaning of the extraction tables from the slag and dross and give access to small details, that may fall inside the table during cutting.

This solution saves time when cleaning and maintaining the machine, without the need for time-consuming removal of the grate.

Additional options available:

CAD/CAM Software

The software is selected based on the customer’s production profile. Our specialized sales department will determine your needs on the basis of a short conversation and then propose the most optimal solution. For more information, call: +48 730 850 710

Modern plasma units

A plasma unit is a key element of any production. Cutting in the range of 0.5 – 100 mm of black steel, aluminum, stainless steel and galvanized steel.

Contact us

Do you have questions or you are interested in the product and would like to receive an offer? Call us on +48 730 850 710, +48 570 740 950 or fill out the form below.

PL

PL

DE

DE  RU

RU