Machine designed for the most demanding customers who expect the highest precision and efficiency. It can be configured with the latest CNC PRODUCTIVITY PLUS software, which gives many possibilities to adapt the machine. It can be equipped with several cutting supports, it can have several pneumatically simultaneously controlled torches on one support, which allows for combining plasma, oxy-fuel cutting and engraving in one program.

| Width | 1500 – 5000 mm |

| Length | 3000 – 24000 mm |

| Travel speed | 50 m/min |

| Accuracy | +/- 0,1 mm |

Solutions that you receive as standard:

Up to 120 m2 of work area

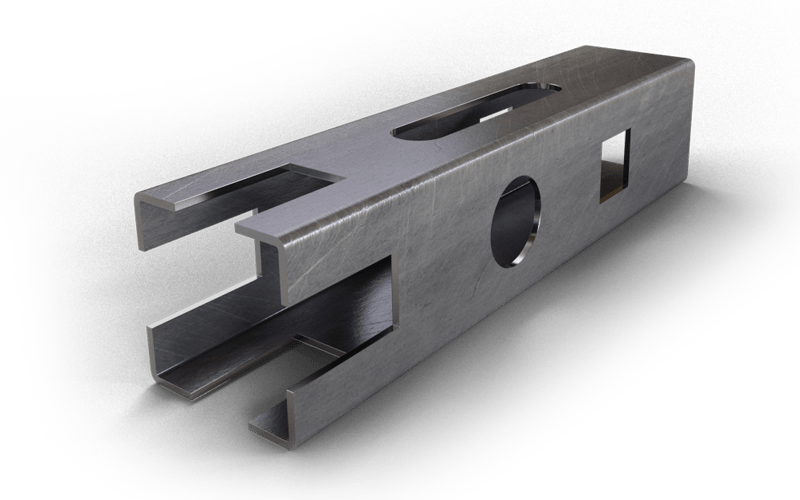

The machine, thanks to its design, allows for the largest working area of all available machines of our company. Such a large surface allows the use of several independent portals with different burners, which can cut 2 or even 3 products independently of each other at the same time. The solution most often used in very large production plants and shipyards. To further expand the production possibilities, the machine can be equipped with an extension of the portal beam, thanks to which it is possible to cut large-size elements, such as profiles, hebes or pipes.

The first Polish machine with Frog Jump system

Glimmer HeavyDuty is the first Polish machine that allows the use of the latest Frog Jump technology to optimize the movement of the torch between vectors. It allows you to save up to 25% of cutting time, which translates into an increase in production efficiency by up to 15% on the scale of one shift.

Multiple brackets

Each portal mounted on the machine can be equipped with several independent tool supports offering various applications and cutting technologies.

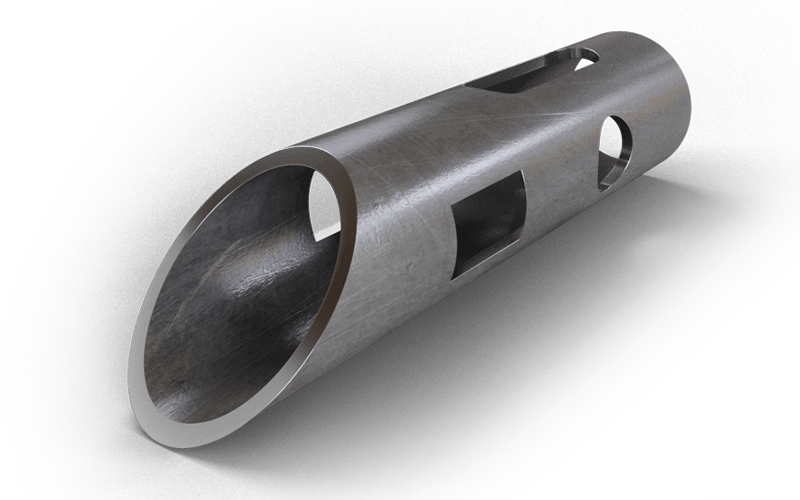

Integration with pipes and profiles turntable system

The cutter can be integrated into the turntable for cutting pipes or profiles. The extension of the portal beam allows for cooperation with an external device, thus enabling cutting outside the working area of the table. A unique solution is a turntable designed to rotate both pipes and profiles, giving the machine even greater versatility.

Mobile control panel

All our dual-support plasma-oxygen cutters are equipped with a movable control cabinet, the range of which can be up to 5m. Thanks to this solution, it is much easier and more convenient for the operator to control the operation of the machine.

Inside the desktop is all the electronics that control the device. Thanks to the quick coupler system, the desktop can be disconnected from the machine in a very fast and easy way.

Hearth drawers

Most of our devices are equipped with waste drawers, which allow easy cleaning of the extraction tables from the slag and dross and give access to small details, that may fall inside the table during cutting.

This solution saves time when cleaning and maintaining the machine, without the need for time-consuming removal of the grate.

Additional options available:

CAD/CAM Software

The software is selected based on the customer’s production profile. Our specialized sales department will determine your needs on the basis of a short conversation and then propose the most optimal solution. For more information, call: +48 730 850 710

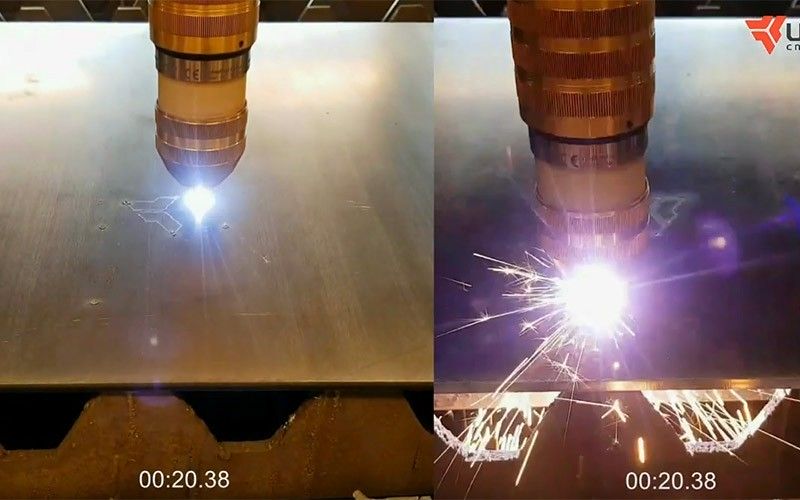

Modern plasma units

A plasma unit is a key element of any production. Cutting in the range of 0.5 – 100 mm of black steel, aluminum, stainless steel and galvanized steel.

Contact us

Do you have questions or you are interested in the product and would like to receive an offer? Call us on +48 730 850 710, +48 570 740 950 or fill out the form below.

PL

PL

DE

DE  RU

RU